our service for Cfd and scaling validation includes:

- Definition of scope of testing (review of documents)

- Communication with Flag, Class society or Independent Lab

- Project Management and organisation

- Document preparation

- Commissioning on the test site

- Testing with adequate organisms according to the calculated dose

- Evaluation and reporting (final report and discussion with authorities)

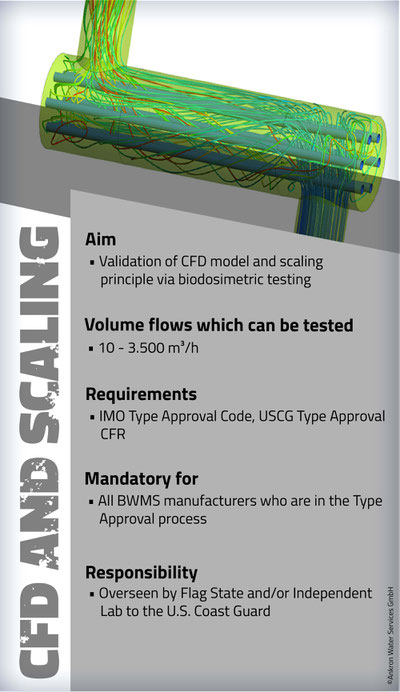

CFD Validation and Scaling of UV Systems

The scaling of water treatment systems is a fundamental part of the product design and the approval process.

Chemical treatment systems are mostly approved based on CFD calculations and dose measurements on board or during land-based tests (i.e. simulation of mixing of active substance and neutralization agent).

For UV systems the scaling can often be more complex and requires a more intense validation of the CFD model, especially because UV dose cannot be measured directly.

A solid, efficient and reliable way is to use biodosimetric testing for the CFD and/or scaling verification.

Biodosimetric Testing with Ankron

The general test plan and validation procedure, developed by Ankron, is based on the UVDGM process but adjusted to meet the needs for ballast water system scaling verification.

The test centre is accredited for the testing of UV systems according to DIN EN ISO/IEC 17025 and can test with different organisms depending on the applied dose of the UV reactor. Besides the determination of the reduction equivalent dose (RED), another great advantage of the test centre is the wide range of testable volume flows (testing from 25 m3/h up to 3.500 m3/h).